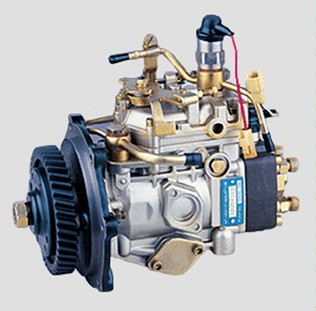

Diesel oil dispensing pump

The people described frequently the engine is automobile's heart, but blows the system is diesel engine's heart. Its product quality, the assembly adjust and use the service to diesel engine's power performance, the oil consumption, the emissions and the service life decisive function. Therefore diesel engine's blow system is the modern diesel engine automobile key core system, is also in the diesel engine automobile service the specification is high and the difficulty big project. Since 1985, our country has introduced J series which the Japanese 50 bell company N series light truck uses to spurt the Sophie 8140 series which successively the type diesel engine, the Italian Iveco light passenger train uses to spurt the type turbo-charged diesel engine as well as the American Commings Company's B series straight straight spurts the type diesel engine straight and so on. Introduction these were equal to the overseas the 1980s advanced level automobile diesel engine install the VE assignment type injection pump which company produced with the German Abundant World Company or the Japanese Light display Company and Jake the Syre.

Until now, our country installs the VE assignment type injection pump's each kind of automobile diesel engine's inventory to have several hundred thousand, the market service quantity is quite considerable. But, produces with our country with the use history long in-line type plunger injection pump compares, because the VE assignment type injection pump is short in our country's period of revolution, the structure type and the appendix type are also many, many automobile diesel engine's use and the servicemen to the VE assignment type injection pump's basic structure, the principle of work, the use serviced and assemble aspect and so on adjustment knowledge still to lack the basic understanding, caused to use the question which and in the service appeared to be many, because often used or adjusts improper causes the automobile power to be insufficient, even braved the black smoke massively and so on adverse consequences. Therefore, we introduced in detail the VE assignment type injection pump's basic structure, the principle of work, the use service and assemble the regulation means that refers for the use and the servicemen in the practical work. First, outline The assignment type injection pump abbreviation dispensing pump, is one kind of more novel diesel engine oil fuel injecting pump. Compares with in-line plunger injection pump, the dispensing pump only uses a pair of plunger matching part to be possible to approach 2~6 cylinders feed. Its structure is simple, the components are few, the volume is small, the quality is light, especially qualify in small high speed diesel engine use.

Therefore, overseas in the compact car, specially on the passenger vehicle obtained the widespread application. The dispensing pump may divide into the rotor type dispensing pump and the single plunger dispensing pump according to its structural style. In the mid-20th century British CAV Corporation has developed the DPA rotor type dispensing pump, in the 60s our country also once imitated the volume production, matches the domestically produced abundant harvest tractor. Because this kind of rotor type dispensing pump performance still had some flaws, the late 70s was the stop production. In the mid-70s, the German Abundant World Company developed the VE single plunger type dispensing pump (as shown in Figure 1). Its structure is simple, the performance is perfect, the volume is small, the quality is light, receives the world diesel engine manufacture manufacturer very quickly the favor, has obtained the widespread promotion, becomes in the world the production lot most multi-cylinder injection pumps.

Afterward, the Japanese Light display Company and Jake the Syre company introduces the German Abundant World Company's patented technology to produce the VE dispensing pump successively. Compares with in-line plunger injection pump, the VE dispensing pump has many merits: 1. the volume is small, the components are few, the quality light (for example Table 1 shows). 2. the feed uniformity is good. The VE dispensing pump's feed uniformity guaranteed completely by the manufacture precision that is helpful in reduces diesel engine's noise. 3. the high speed compatibility is good. In-line plunger injection pump highest rotational speed is 2000r/min, but the VE dispensing pump may achieve 3000r/min. 4. in-line injection pump fuel oil and the lubricating oil separate, the leak-proof request is high, once the diesel oil divulging dilution machine oil, will accelerate the part to wear, easy to initiate the breakdown. But the VE dispensing pump pump body interior fills the diesel oil, has the self lubrication function, does not need the regular replacement machine oil. the 5.VE dispensing pump's each kind of control mechanism has the relative independence.

May according to diesel engine's different need, combine the corresponding control mechanism. the 6.VE dispensing pump uses the solenoid valve control fuel oil the make-and-break, on automobile's operation nimble convenient. the 7.VE dispensing pump has against reversal function, may prevent the diesel engine reverse. the 8.VE dispensing pump's is nimble on diesel engine installment position, horizontal, the vertical installment may. Compares with in line pump, the VE dispensing pump components' working accuracy request is high, moreover is strict to the material material quality and the heat treatment request, is also harsher to the diesel oil cleanliness's request. Satisfies these conditions to be able to guarantee injection pump's normal work and the proper service life. VE dispensing pump's basic strokes specification as shown in Table 2, its serial number method and the meaning showed that as shown in Figure 2. Second, basic structure and principle of work 1. basic structure and function VE dispensing pump blow system's oil duct as shown in Figure 3. Before the diesel engine starts, uses the manual pump oil pumping first, removes in the diesel oil pipeline's air through roof panel's on overflow valve. When the diesel engine moves, drives dispensing pump's drive shaft by the crank gear. Its front end gleitbretter type feeding pump extracts the diesel oil from the fuel tank, passes through the diesel oil filter and the oil-water separator, after filtering out in the diesel oil the impurity and the moisture, enters the feeding pump, causes diesel oil pressure lifting. Then enters in the dispensing pump pump body, enters the plunger cavity again after the solenoid valve. When plunger upward movement, the compression diesel oil produces the high pressure, after plunger's in oil lead and the oil hole, assigns to the pump body on the corresponding cylinder's oil lead, again after the delivery valve, the high-pressure oil pipe and the spray hole gushes in corresponding the cylinder. In the pump body the unnecessary diesel oil's returns to the fuel tank from roof panel overflow valve. The diesel oil so circulatory flow both may carry off the quantity of heat which in the oil duct the air bubble and the components friction produce, and may lubricate the individual movement components.

Meanwhile, in the pump body diesel oil pressure control, changes the advance angle of fuel correspondingly ahead of time. The dispensing pump is in system's core part (as shown in Figure 4), it is mainly composed of the following four parts: (1) the transmission feed part (as shown in Figure 5) The drive shaft leads plane cam drum revolving through ten character shaft couplings, leads plunger revolving again. The plunger spring and the spring holder press the plunger on the cam drum, causes the plunger to make the reciprocal motion during revolving. Thus, in the plunger cavity's diesel oil both are compressed produces the high pressure, and the oil hole assigns through the plunger to the pump body on the corresponding cylinder's oil lead, after the delivery valve, the high-pressure oil pipe and the spray hole gushes in corresponding the cylinder. (2) modulates velocity the control section (as shown in Figure 6) On drive shaft's gear leads flies the hammer place and flies hammer revolving, flies hammer's centrifugal force impetus velocity modulation sleeve end motion. Moves on plunger's fuel flow control sleeve after the speed adjusting gear along with the rotational speed change, but about moves, changes its right flank leng side the radial direction unloading hole relative position (as shown in Figure 4) with the plunger on, thus achieves along with the rotational speed change controls the fuel feed change the goal. (3) rolls the wheel seat and ahead of time (as shown in Figure 7) Rolls on the wheel seat to be loaded with four hoops, through cylindrical pin and ahead of time piston joint. When in pump body diesel oil pressure variation, promotes ahead of time the movement of plunger, drives the cylindrical pin to cause to roll the wheel seat rotation, the change hoop and the plane cam drum bulge relative position, thus achieves the change feed angle of advance the goal. (4) the feeding pump and the pressure-regulating valve (as shown in Figure 8) When the gleitbretter type feeding pump revolves, as a result of rotor and pump housing bias, between gleitbretter's volume change, but pressurizes the diesel oil to 0.6~0.8 MPa, enters the pump body cavity, but the pressure-regulating valve uses for to adjust the diesel oil pressure.

When the diesel oil pressure is too high, the accent presses the piston to open the oil discharge mouth, the diesel oil returns oil inlet, causes the drop of pressure. The pressure is higher, the spring reduces the quantity to be bigger, the oil hole opening cross-sectional area is bigger, the oil discharge quantity are more, plays the automatic control oil transfer pressure the role. As a result of pressure-regulating valve's function, the flowing tubing head pressure which the feeding pump produces (i.e. engine speed) increases along with the oil pump rotational speed is proportional the enhancement, thus makes the feed angle of advance along with the rotational speed to enhance, but the linearity enlarges, satisfies the diesel engine highly effective combustion the request. 2. feed and assignment basic principle The VE assignment pump plunger shaft, the distributor barrel (i.e. column sleeve) and plane cam drum's relative position as shown in Figure 9. First introduced that the cam and the plunger progress, the fuel tank phase. Speaking of four cylinder diesel engines, on dispensing pump's plane cam drum has four section of cam form lines, is separated mutually 90; Rolls the wheel seat Chinese dress to have four hoops, is separated is also mutually 90.

The plunger peak has four oil-feed tanks, in the circumference has a fuel tank, in the corresponding distributor barrel has an oil in and four oil holes. Oil pump drive shaft each extension 90, in the cam and under plunger spring's coordinating role, pulls pushes about the plunger reciprocal motion time at the same time to rotate 90, the plunger correspondingly completes one time enters the oil, the pressure oil and the assignment feed process. Such feed process is redundant four times, separately to four cylinder blows. In a diesel engine's operating cycle, assigns the pump driving shaft to revolve for one week. Speaking of six cylinder diesel engines, on dispensing pump's plane cam drum has the cam form line, is separated mutually 60; Rolls the wheel seat Chinese dress to have four hoops, but is separated mutually respectively be 60 and 120. The plunger peak has six oil-feed tanks, but in the circumference still only then a fuel tank, in the corresponding distributor barrel also had an oil in and six oil holes. Oil pump drive shaft each extension 60, the plunger has completed one time enters the oil, the pressure oil and the assignment feed process. Such feed process is redundant six times, assigns the pump driving shaft to revolve for one week. Regardless of being four cylinder dispensing pumps is six cylinder dispensing pumps, the plunger completes one time enters the oil, the pressure oil and the assignment feed process is the same, presently relates in detail as follows:

(1) enters the oil process When two-dimensional cam peak and hoop contact, the plunger is in the top dead center. The plane cam drum continues to rotate, the hoop slides along the two-dimensional cam drop section, the plunger downward and also revolves, in its oil-feed tank and distributor barrel's oil in connection, this time on the plunger the fuel tank has transferred in the distributor barrel the oil hole to shut down, the diesel oil enters the plunger cavity after in the solenoid valve and distributor barrel's oil.When the plunger arrives at the bottom dead center to enter oil end of process, the two-dimensional cam revolved to the bottom and the hoop contact.

(2) reduces the injection process When the plane cam drum continues revolving, the hoop raises along the cam ascent portion, above the plunger upward compression diesel oil, and simultaneously revolves causes the oil-feed tank to transfer in distributor barrel's oil to close. But leaves in the fuel tank and the distributor barrel the oil hole connection, continues along with the plunger upward, the high-pressured diesel oil after the delivery valve, the high-pressure oil pipe and the spray hole gushes in the cylinder.

(3) feed conclusion When the plunger rises to the certain extent, on plunger's unloading hole reveals control sleeve's control plane, in the plunger cavity high-pressured diesel oil after plunger's central oil lead unloading, the flowing tubing head pressure drops rapidly, feed conclusion.

(4) presses the process (as shown in Figure 10) After feed conclusion, the plunger revolved to it presses in the position which in the trough and the distributor barrel the oil hole is interlinked, leaves between the oil hole and delivery valve's assignment oil lead presses the trough and the ring groove and the pump body cavity connection through the plunger on, causes between various cylinders this section of assignment oil lead the pressure before spraying starts maintains consistent, thus improves between the dispensing pump various cylinders' feed uniformity. VE the dispensing pump uses the change feed completion point relative cam the position (i.e. on control sleeve's control plane and plunger unloads hole relative position), changes the feed effective travel (as shown in Figure 11).

And shoulders the regulating control sleeve's position by the velometer according to the rotational speed, its control plane toward right, the unloading hole reveals the phase is later, the feed conclusion was later, the feed effective travel was bigger, the fuel feed were more. Otherwise, fuel feed reduction. 3. stops the oil solenoid valve As shown in Figure 12, stops the oil solenoid valve's electric circuit by the ignition lock control: When the ST - - diesel engine starts, the solenoid valve supplies power directly by the automobile accumulator cell, the voltage is high, overcomes the spring strength to open rapidly. When ON - - diesel engine normal work, the solenoid valve has electrified. In order to reduce the solenoid valve to give off heat, lengthens solenoid valve's service life, connects into a voltage dropping resistor, causes the electromagnetism valve voltage to reduce to can the maintaining valve core hold is opening the position the minimum value. The OFF - - solenoid valve power failure, the valve core takes a seat under the spring strength's function, shuts off the oil channel, the diesel engine engine off.